Our Background :

Giv Engineering design innovative & high utility products and develop them for mass manufacture. Using design strategy & step-by-step process, we work with you to create the product, packaging, and business presentation you need to confidently pursue your business goals, knowing you have access to engineering, design and commercialization support at all times.

Our Goal:

- To provide low cost and professional engineering design services.

- To meet marketing, regulatory and user’s requirements with reasonable manufacturing cost and high quality expectations.

- To use project management tools to plan , create, review and refine a solution with our clients to achieve both risk mitigation and development speed.

- Tweaking project targets as per your needs to manage Project timeline & ensures your projects moves smoothly through to production.

- Weekly updates reports on project stages and interact directly with client using online video portal.

Our Services :

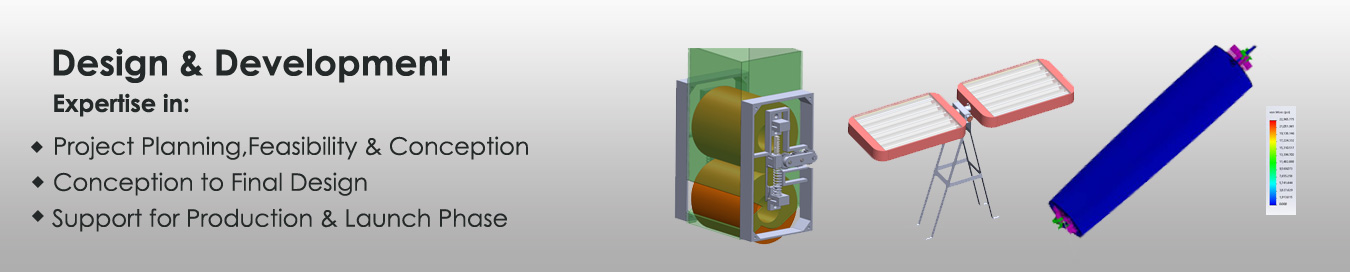

For all projects, we follow a strategic path for product design & development process that highlights our services thru each stage to ensure critical issues are identified & rectified before moving on to consecutive development stages . It is based on multiple iterations that produce concrete ideas and prototypes that can be viewed, assessed, tested, and refined.

Stage 1: Project Planning & FeasibilityStage 2: Idea ConceptionStage 3: Concept to Final DesignStage 4: Product Validation & VerificationStage 5: Design to ManufacturingStage 6: Product Launch

SERVICES :

- Project objective – Design goals etc.

- Project Timeline – Gantt charts

- Project Pre-budget Info.- Cost estimation.

- Preparing necessary Approval Documents.- NDA etc.

- Creating Product Design Proposals.

- Conducting for competitive Product benching marking research for such as – Expectations for end users, Performance parameters, Manufacturing strategies, Cost targets, and more.

- Conducting Feasibility Studies.

SERVICES :

- Identifying Potential concept Ideas.

- Creating 3D CAD Design Concepts using CAD Software.

- Conducting Initial DFMEA & FEA.

- Conducting checks for Design Level Regulatory compliance.

- Prepare Clients specific Power Point presentation with Product Photo realistic renderings.

- Conduct multiple iterations presentations with clients for sustainability, efficiency & manufacturing processes.

SERVICES :

- Prototyping – using readily available materials , 3D print parts etc.

- Evaluating concept for fit, function, appropriate DFM and DFA qualification.

- Conducting Specific Regulatory requirements checks.

- Conducting Final DFMEA & FEA.

- Preparing final design file with 3D CAD & Risk Mitigation reports.

SERVICES :

- Liaison for Product testing quotation.

- Identifying Potential testing facilities for validation.

- Identifying potential customer base for Product trials.

- Support for conducting Product Validation tests using various authorized testing facilities.

- Manufacturing Support of Prototype units for product trials.

SERVICES :

- Preparing 2D drawings, Assembly drawings, B.O.M. & Material Specs etc.

- Vendors sourcing.

- Product manufacturing Support such as jigs, fixtures, work instructions etc.

- Initial production test sampling.

- Quality management for root cause analysis.

SERVICES :

- Preparing User’s / Owner’s manuals.

- Product Brochure.

- Final Project Design Document Transfer.

- Customer Feedback Support Processes.